| Model | Mounting Category | Working Width (m) | Rotors | Power Demand hp | PTO rpm |

|---|---|---|---|---|---|

| TD 524 | Cat I + II | 5.2 | 4 | 30 | 540 |

| TD 676 | Cat I + II | 6.6 | 6 | 41 | 540 |

Key features

WORKING WIDTHS

5.2m – 10.2m

MOUNTING

CAT I + II or SWIVEL

PTO RPM

540

TYNE ARMS/ROTOR

6

STANDARD

TYNE PROTECTION

ROTORS

4-8

Models

3 Point Linkage Tedders

Trailed Turbo Tedders

| Model | Mounting Category | Working Width (m) | Rotors | Power Demand hp | PTO rpm |

|---|---|---|---|---|---|

| TD 775 TRC | Drawbar | 7.7 | 6 | 41 | 540 |

| TD 868 TRC | Transport Chassis | 8.6 | 8 | 447 | 540 |

| TD 10208 TRC | Transport Chassis | 10.2 | 8 | 54 |

Key features

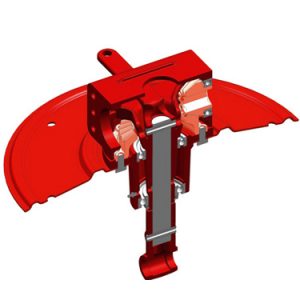

The tyne arms are made of a tough, galvanised flat steel bar, which allows a wide contact surface between tine and rotor disc. This ensures excellent power transmission even under the harshest of working conditions. The forces are optimally absorbed whenever the ground is uneven. All Massey Ferguson hay tedders are equipped with a novel tyne saver as a standard feature, which protects machines which are following behind and also your valuable livestock. The tynes are secured under the tine arm. On the one hand, this arrangement has the advantage that the upper side is smooth and, as a result, no forage can be left hanging. On the other hand, it allows the tyne greater freedom of movement, which contributes to optimal processing of your high-quality forage.

All round tedders, thanks to the excellent quality of work they produce and their flexibility of use.

Massey Ferguson rotor heads have an enclosed design which protects all important components from dirt and dust. This design provides years of trouble-free service.

The individual rotors are driven via a generously dimensioned hexagonal shaft and robust universal joints. This type of power transmission is free from backlash, smooth and reliable.

All hay tedders are equipped with thickwalled, strongly dimensioned square frame tubes which ensure excellent rigidity and a very long service life. The individual rotor frames are connected via sturdy frame joints with special flange sleeves and hardened pins. All joints can be relubricated and are of robust design. This contributes to ensuring optimum ground adaptation even after many years of service.

The Super C quality feature guarantees a high level of quality and represents an extremely long service life. The tines used at Massey Ferguson have to undergo a test cycle and survive 200,000 impacts without damage. Only then may they be fitted on Massey Ferguson machinery. As early as the manufacturing stage, special process steps are used to design the tines for toughness, elasticity and durability. The Super C tine has a tine diameter of 9.5 mm, a winding diameter of 70 mm and six windings, making it one of the most efficient on the market and typical of the high manufacturing quality of each and every Massey Ferguson hay tedder.

Only equal-sided tines allow you to achieve an optimum mixing of your high-quality forage. This is known as the comb effect since, during the process the different layers of forage are perfectly mixed together and turned, providing the optimum production of high-quality forage. Tines with sides of equal length also provide the benefit that you do not need right-hand and left-hand tines but only one kind of tine, which makes spare parts management easier.