| Model | Bale Size WxH (mm) | Plunger | Pick-up Working Width (mm) |

|---|---|---|---|

| MF 1840 | 356 x 457 | 100 storkes/min. | 1900 |

Models

Features

- Width

- In-Line design

- Superior Feeding

- Crop Flow

- Adjustable Drawbar

- Knotter Design

- Twine Storage

- Pick-up

- OpiForm Bale Chamber

- Packer

- Bale Density

- Bale Density Control

- System Control

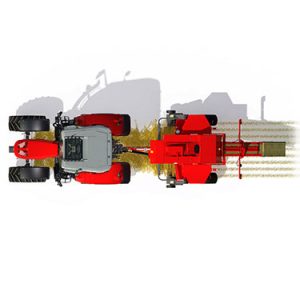

Easy on the road, easy in the field. You’ll notice the first advantage before reaching the field. Even though the MF 1840 features a wide pick-up, transport width is exceptionally narrow because of the in-line design allowing easy access to narrow lanes and awkward gateways. And when you get to the field, there is no need to manhandle the baler from a ‘transport’ position to a ‘work’ position – you just lower the pick-up and start baling.

The unique centre-line construction is designed to run in-line directly behind the tractor for unrivalled convenience and field efficiency. In addition it also gives you better weight distribution and reduces ground compaction.

The 1.9 metre wide pick-up features a small diameter, ‘low-profile’ design with closely spaced tines ensuring that windrows are picked up cleanly with minimal disturbance and leaf loss. Gauge wheels, fitted as standard to either side, further help the pick-up to follow uneven ground contours, avoiding pick-up tine damage.

The crop is delivered into the pre-compression chamber where the flake is pre-formed before entering the main chamber. This ensures a well-shaped bale is formed improving bale density and reducing stress on components giving improved baler durability. With a short stroke and high speed plunger, the pre-formed slice concept enables the baler to operate with high capacity, significantly reducing plunger bearing wear whilst generating a greater number of bales.

An adjustable drawbar provides various settings to enable the machine to be coupled to a broad range of tractors.

The Hesston design of knotters are built to operate reliably season after season, with minimum fuss or maintenance. Their rugged design guarantees excellent reliability bale after bale, whether using high quality twine.

An electric knotter fan is fitted as standard to the MF 1840 and ensures the knotter are kept clean and free from any debris build up during operation.

The MF 1840 carries 10 balls of twine which is enough for the longest days work. The large dimension of each compartment allow ‘super large’ size twine spools to be used, enabling even more twine to be carried and therefore more bales produced per twine fill-up.

The 1.9m wide pick-up is equipped with ‘up-turning’ augers, which convey the crop up and across the front of the flights. This significantly increases capacity and is particularly effective in damp, uneven and difficult crops.

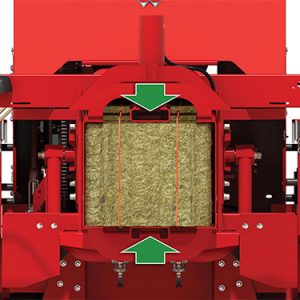

To ensure superb bale shape in all conditions and maintain consistent density, the OptiForm bale chamber is 460 mm or 30% longer when compared to the previous MF 1839 baler.

The packer design increases feeder capacity in a range of crops and conditions.

Uniform bale shape and density throughout the whole bale is ensured by the OptiForm bale chamber, which has been increased in lengthy by 30%. This helps flakes to form evenly delivering consistency across the entire height and width.

The system automatically regulates pressure on the pressure rails of the OptiForm bale chamber to ensure consistent bale density as conditions vary across the field and throughout the day.

A small hydraulic reservoir, pump and pressure regulator at the front of the baler control the oil pressure in the density control rams.